We can customize the laminating area and chamber combinations to meet various customer requirements, allowing for greater production capacity and shorter processing cycles. Additionally, the loading and unloading forms can be tailored to customer specifications, such as stacking or lifting forms. This flexibility enables us to effectively address the technical needs of packaging customers across different industries.

We can customize the laminating area and chamber combination according to different customer needs to achieve greater production capacity and shorten the process cycle. The input and output forms can also be equipped according to customer needs, such as stacking form, lifting form, etc., and can be freely matched, greatly meeting the technical needs of packaging customers in different fields.

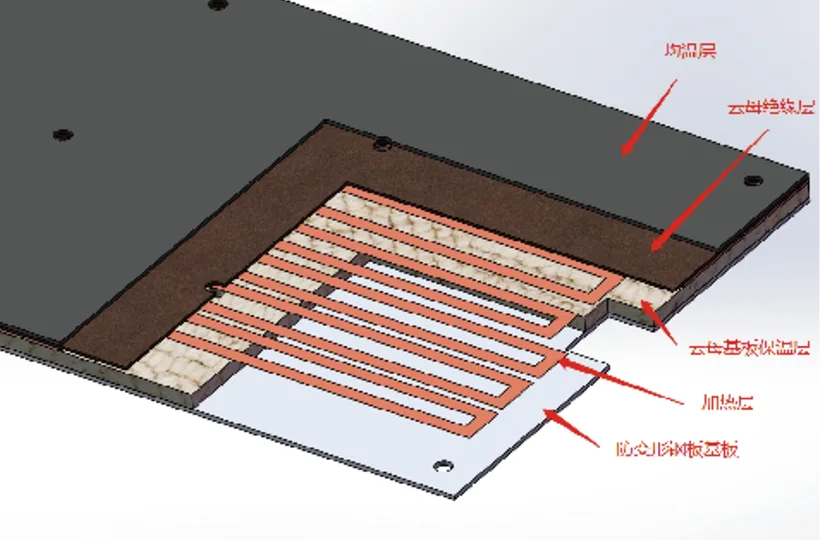

The basic principle of the electric heating plate: adopts install the heating element onthe lower surface of the heating steel plate for heating.

The electric heating plate adopts a composite structure, lt is composed of asubstrate, an insulating layer, a heating layer, an insulating layer, and a temperaturequalizing layer.

Adopt aluminum silicate material whose performance is low thermal conductivity and high mechanical strength for heat insulation.